Semiconductor Chip Shortage - Lab 071

About the Episode

Let the chips fall where they may!

There are chips in every computing device out there, from refrigerators to smart phones to cars. They are vital to how our world runs – and right now, there's a shortage. We learn what’s behind the shortage and what’s being done to close the gap.

Depending on where you look and when you look, you may find sources telling you the chip supply is down and others saying there are so many excess chips that prices are dropping. In this lab we tried to understand the current state of things, how we got to this point, and policies & organizations working to stabilize the chip supply.

Shortages Exacerbated by the Pandemic

We’re in the age of digitization, and even before the pandemic, there was already some pressure on the chip industry. The semiconductor chip industry has been a prime example of the bullwhip effect for a long time. Concern about chip supply isn’t new and has been around for a long time as referenced in this 1988 NYTimes’ article. In 2020, the pandemic and market shifts in response to it led to even more chip shortage than previously expected.

Auto - Automakers cancelled their chip orders in response to closing their manufacturing plants due to the pandemic (March 2020). If your plant isn't open to build cars, there’s no need to continue ordering chips! Thee basics of economics tell us when there’s no demand, we should pivot, and that’s what the chip industry did - they shifted to more chips for electronic devices. The demand for cars bounced back quick, and by Summer 2020, automakers were scrambling for chips.

Smartphones - Smartphones are a major player in the chip industry, and they didn’t really feel the impact of chip shortages until 2021. This is partly because smartphone manufactures didn’t drop their demand for chips like the auto industry did. If you think about it, the pandemic didn’t cause people to use their devices less; if anything, they used them more! But eventually, even this industry was impacted by the scarcity of chips.

Running a tight chip ship

Manufacturing chips is a very exact process. You need special materials, facilities, and trained labor forces to keep the plants up and going.

As an illustration of how little room there is for error, consider this - a half hour power outage at a chip plant in 2018 caused >$43 million in losses. 30 minutes!

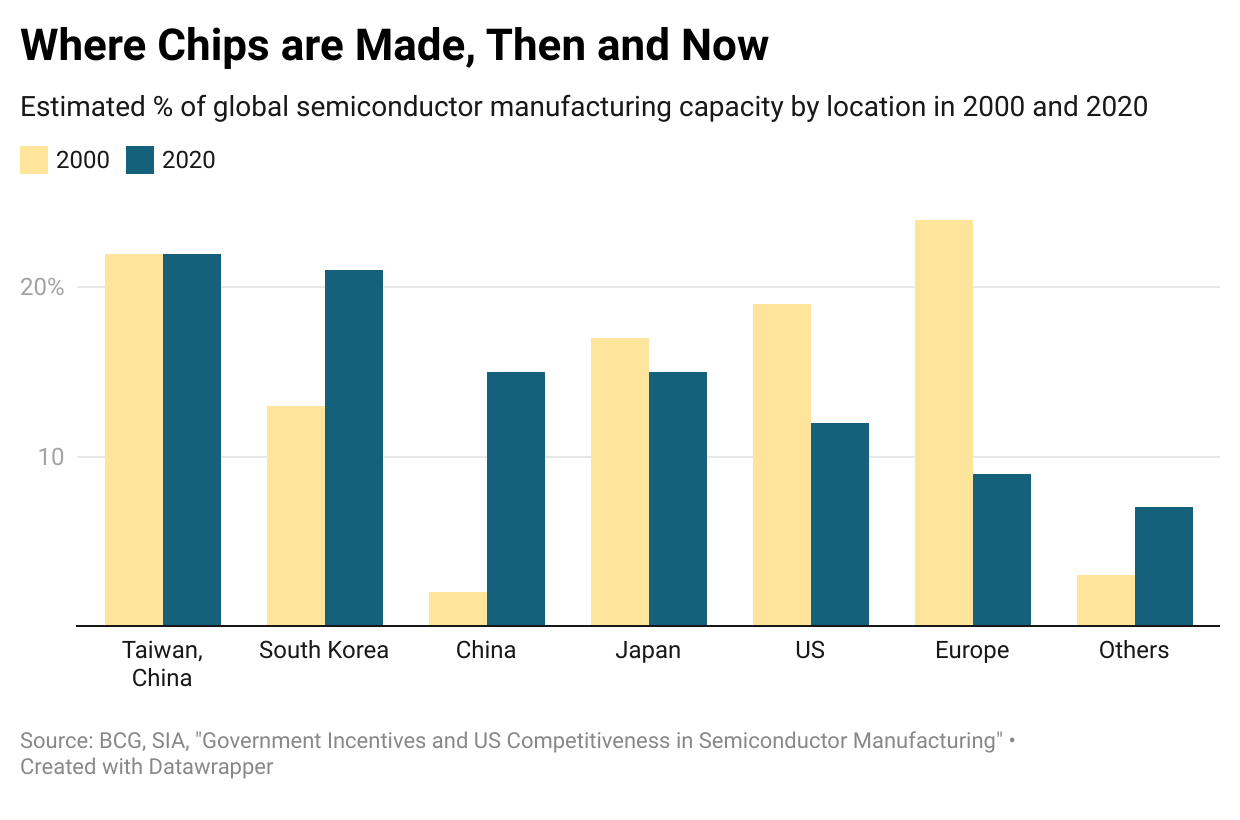

Aside from a quick pivot by the auto industry, the chip industry was also susceptible to supply chain issues in the US (which we discussed in Lab 039: Add to Cart with Christopher Mims) as less manufacturing is done in the states.

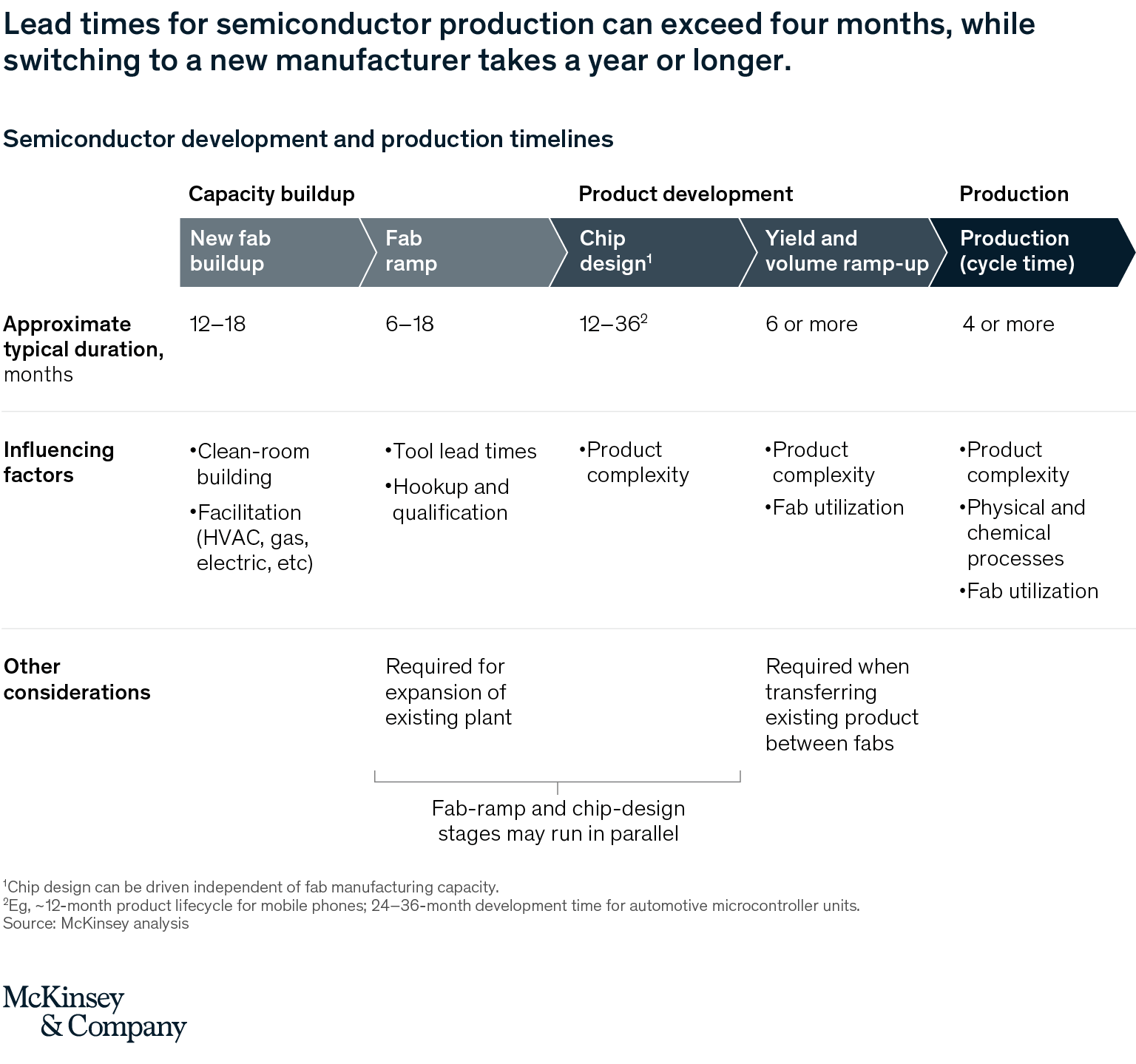

Additionally, responding to changes in demand is not easy. Al told us about the time and resources necessary to build chip fabrications.

Read more

The Jumbled Dream of US Chips, part of the On Tech with Shira Ovide column

Chipmakers refuse to build new US plants without more funding

Chip manufacturers struggling to meet demand amid global shortage

Chip designers warm to US bill despite big benefits to Intel

Guest Expert

Our guest expert for this lab is Al Thompson, Vice President of US Government Relations at Intel.

Listen

You can listen to this lab and others exclusively on Spotify. Click follow to make sure you’re notified as soon as new labs are published!